Mission-critical data centers: massive capabilities, enormous challenges

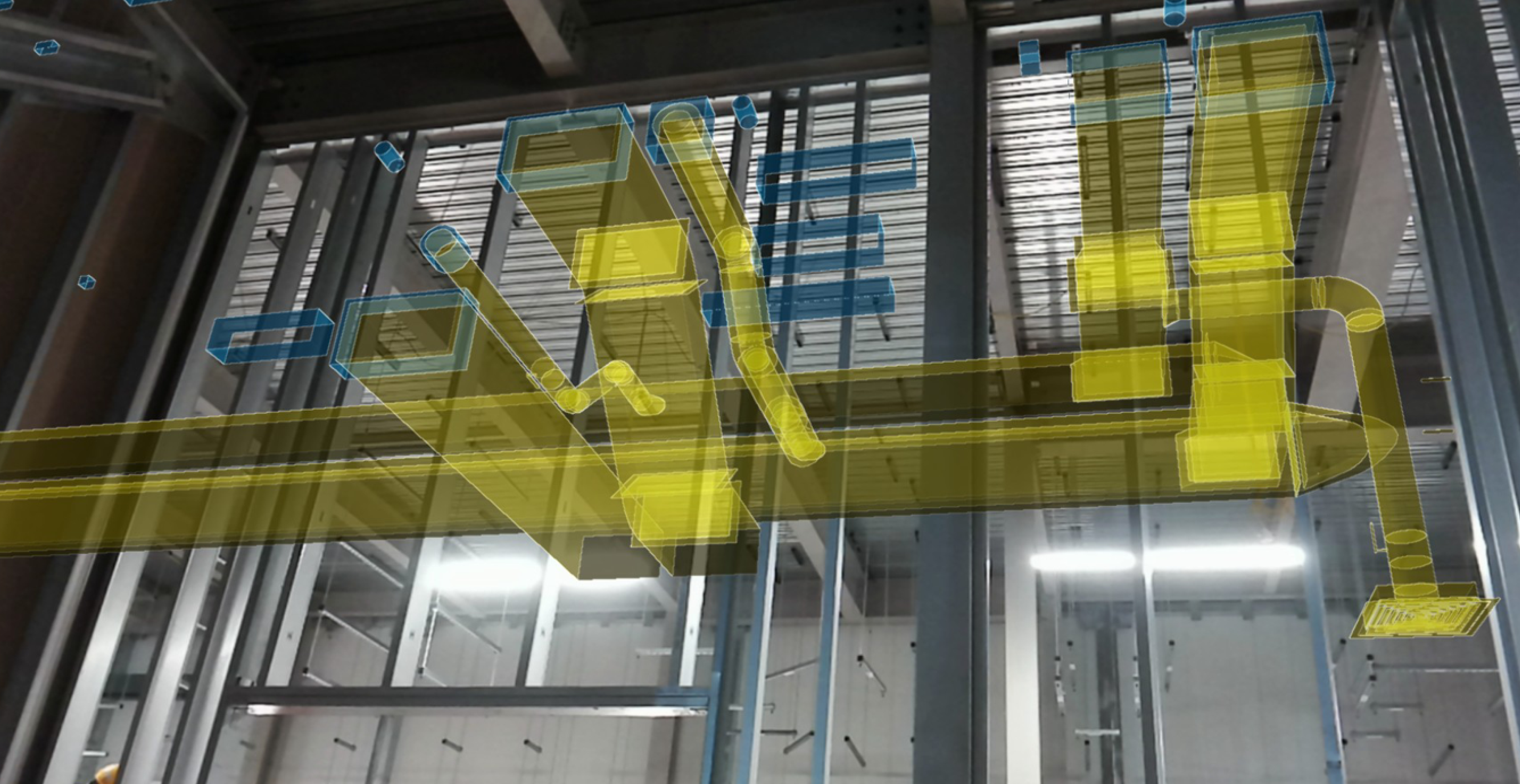

Data centers are increasingly crucial pillars of the world’s infrastructure. But, with their huge scale and multitude of complex interconnected components, their construction presents immense challenges for project teams.

The sheer number of logistical complexities involved makes site clashes and rework virtually inevitable, putting significant strain on budgets and timelines.

Aware of the money and time that could be saved through early discoveries, the general contractor for a Netherlands-based data center sought out XYZ’s expertise and cutting-edge solutions.