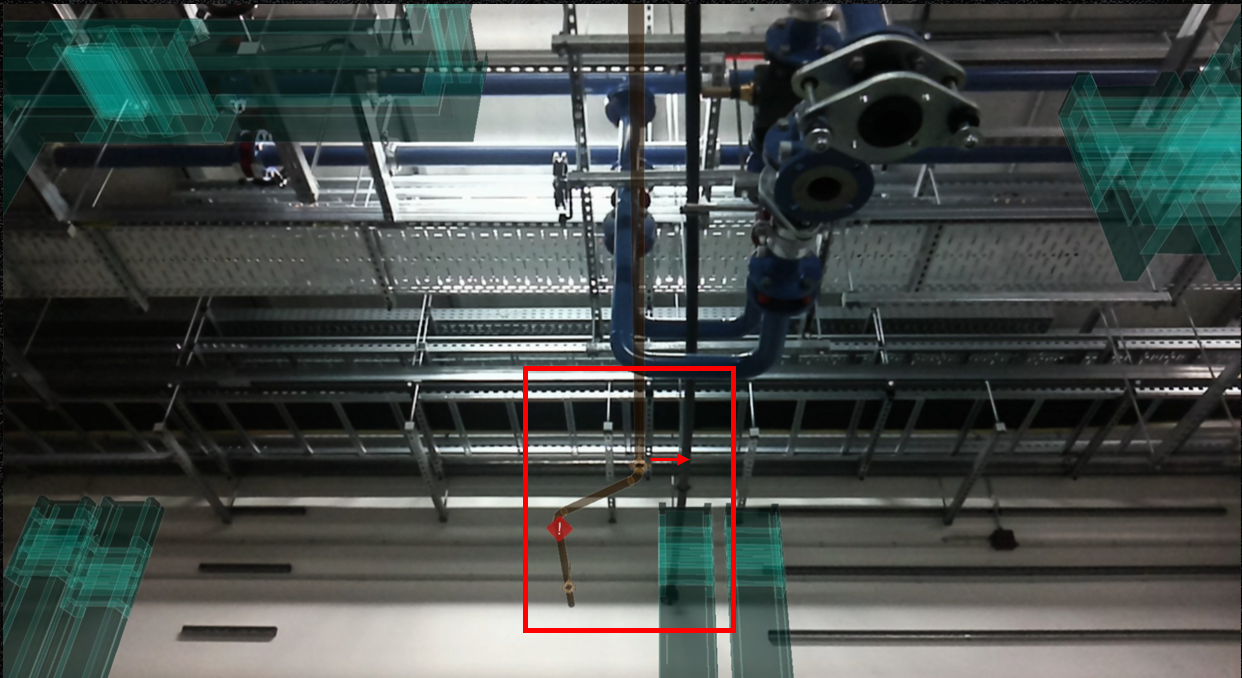

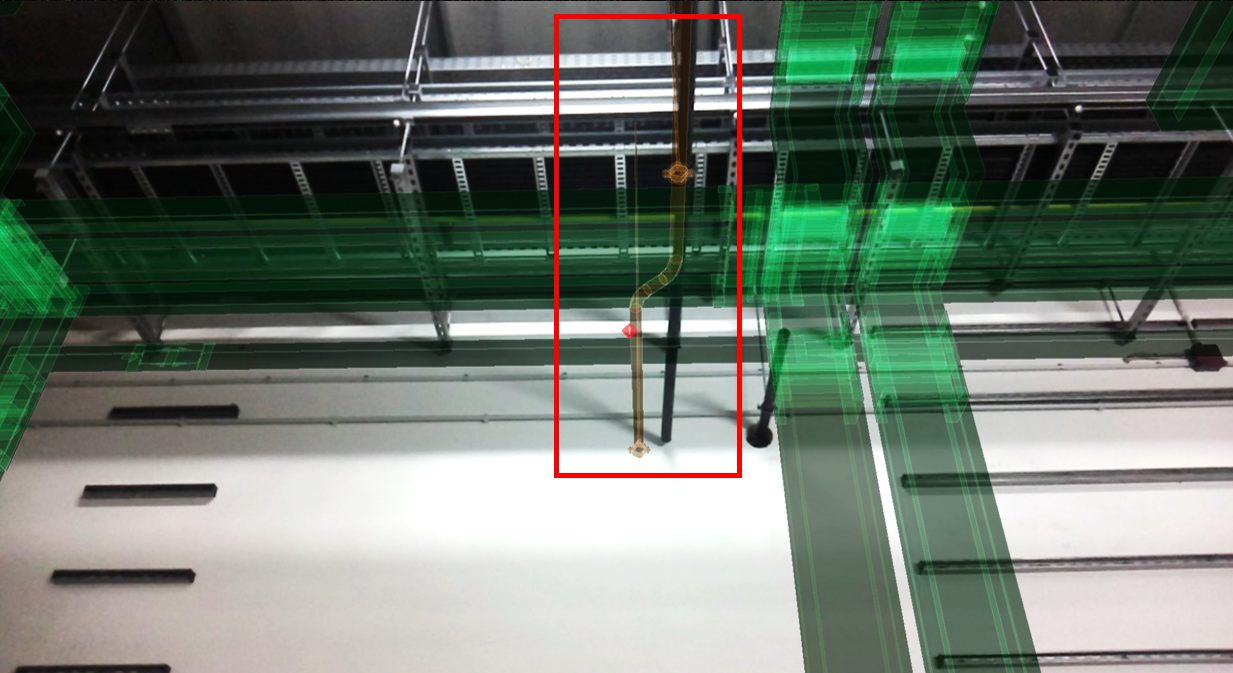

Mission-critical data centers leave no room for error. As trades converge in tight spaces, a single misalignment – especially during the fit-out stage – can trigger weeks of delays, rework, and spiraling costs. That’s why proactive issue identification is more than a best practice – it’s essential to protecting the critical path.

-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions