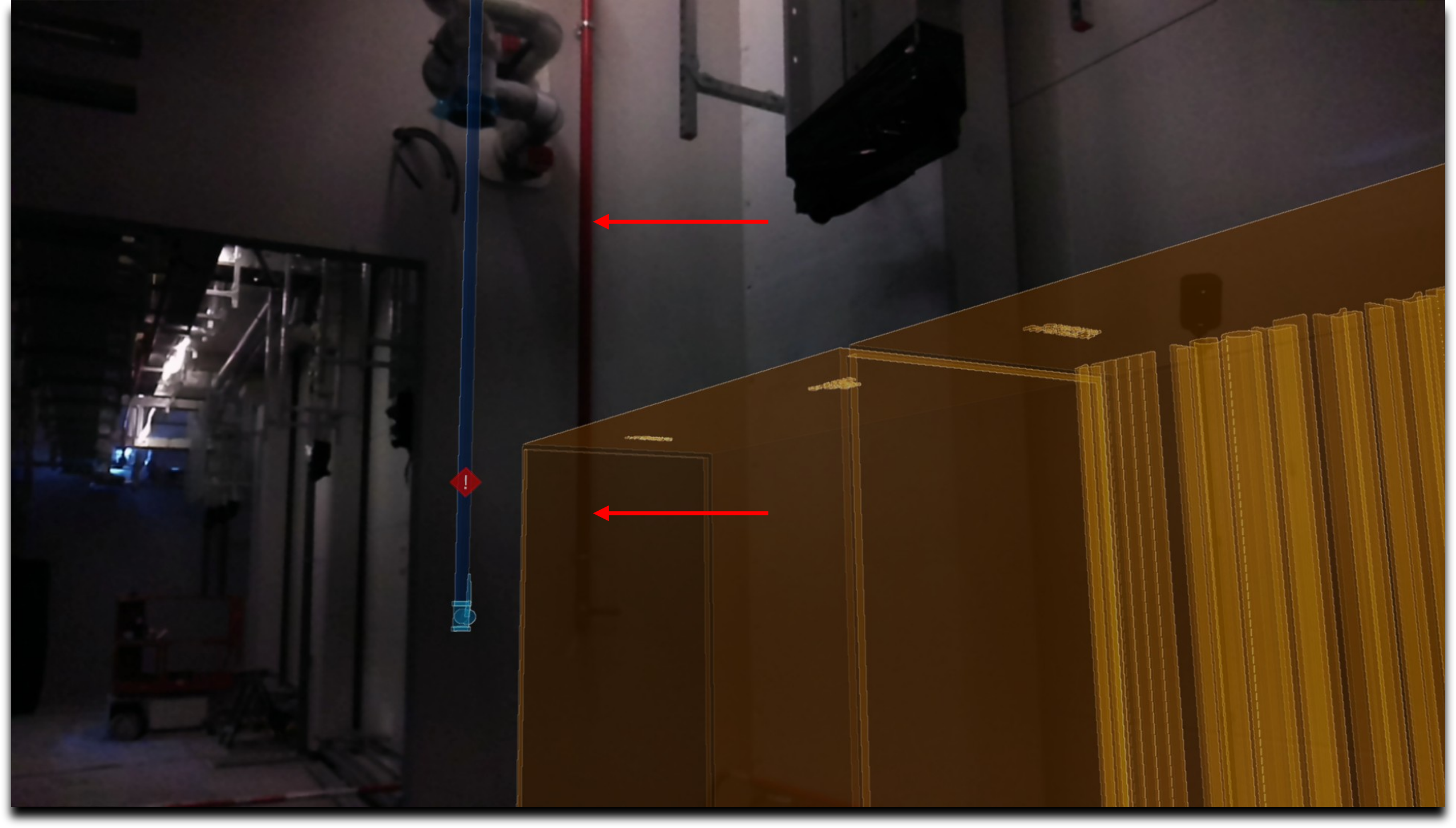

During a France data center fit-out, a misaligned fire pipe threatened to delay critical equipment install. Learn how XYZ Reality’s QA process caught the clash early, eliminating rework and preventing costly disruption.

-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions