-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions

Video

Proactive QA Takes Data Center Construction to New Heights

19 May 2025

In modern construction, speed and accuracy can mean the difference between a smooth project and one riddled with delays and costly rework. Nowhere is this more true than on complex data center builds, where every structural element needs to align precisely to demanding specifications.

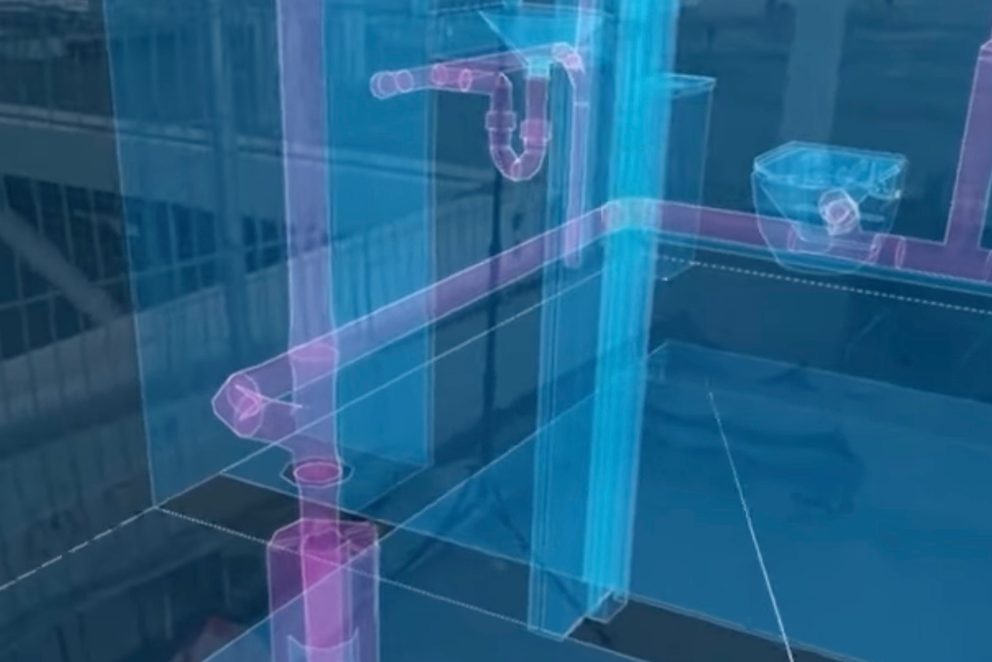

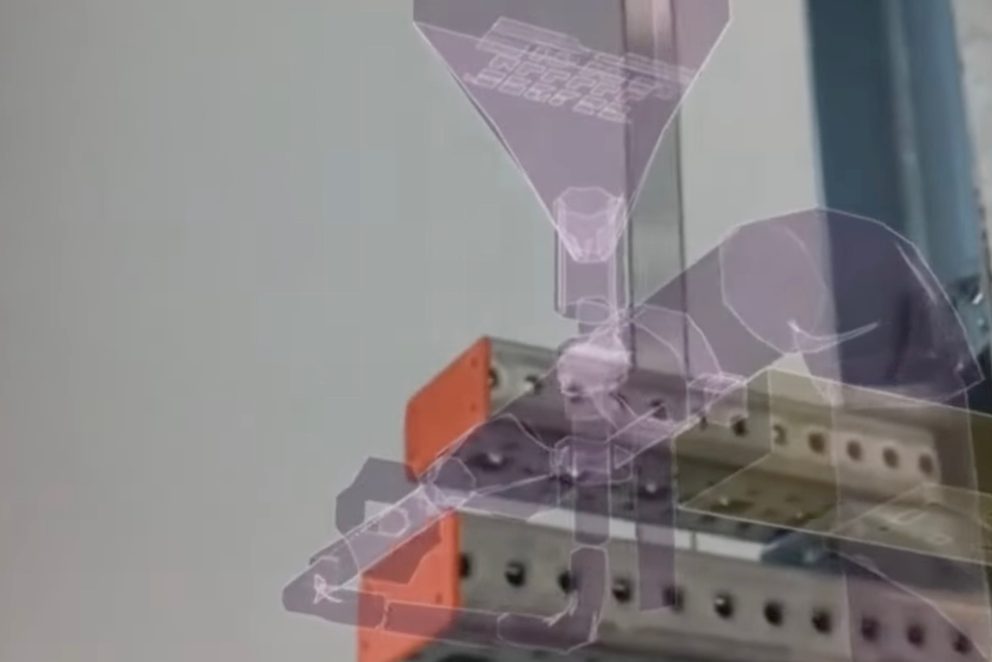

On a recent data center project, our team put proactive quality assurance into action in a groundbreaking way. A site engineer climbed to the roof equipped with the Atom™ headset - not just to check what had already been built, but to look ahead at what was coming next.

Using millimeter-accurate AR visualizations synced to the XYZ Platform, the engineer was able to:

- Verify concrete plinths intended for structural steel installations

- Confirm roof alignment directly against the BIM model

- Flag clarity improvements for client review, ensuring smoother communication

- Inspect future PPR installations virtually before physical work even began.

All of this was done in real time, transforming what would normally have taken hours into a task completed in mere minutes. Issues that might have remained hidden until later stages were uncovered early, giving the team the opportunity to resolve discrepancies before they turned into costly problems.

This proactive approach represents a new era in construction quality assurance. By blending real-time AR insights with precise data integration, teams can make fast, informed decisions with absolute confidence.

This is how proactive QA gets done. This is how we build it right, first time. And this is how projects stay on track, saving both time and resources while delivering the high standards clients expect.

See it live - Book your demo today!