-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions

Video

Avoiding Rework: Real-Time QA in Mission Critical Construction

23 June 2025

Construction success hinges on precision. A single installation error can ripple through schedules and budgets, especially in mission-critical environments where tolerances are tight and timelines are unforgiving.

On a recent mission critical project, our team conducted a routine inspection on a pop-up planned for integration into the concrete slab. What we found could have turned into a significant problem. Instead of being installed as designed, the pop-up was positioned more than a meter away from its intended location. Worse still, it was situated in an entirely different room than shown in the original drawings.

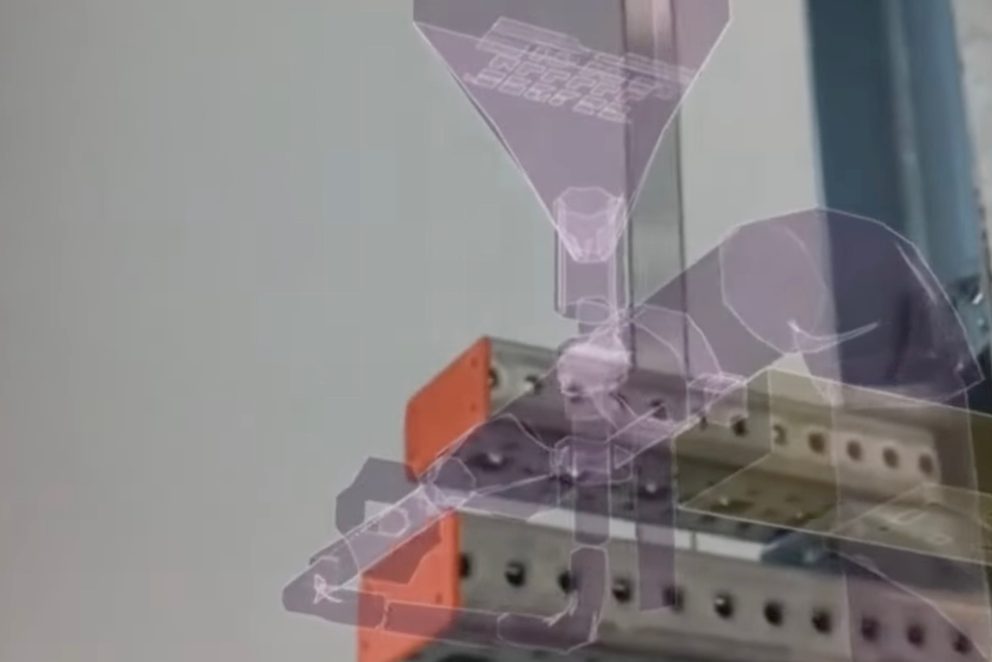

In traditional workflows, such an error might have gone unnoticed until the concrete pour was complete, requiring costly demolition and reconstruction. But this time, we were equipped with XYZ’s engineering grade augmented reality™ (AR) technology.

By overlaying the digital model directly onto the physical environment, we were able to see the discrepancy instantly. The misalignment was confirmed on-site and promptly communicated to both the general contractor and the subcontractor responsible for the installation. Thanks to this early intervention, the pop-up was relocated to its correct position just in time, avoiding what could have been expensive and time-consuming rework.

This incident underscores why proactive QA is so critical in complex construction projects. With AR, teams can catch deviations as they happen, rather than discovering them only after permanent materials like concrete are in place. Catching an error before it’s encased in concrete can save not just money but days or even weeks of project schedule.

In construction, timing and accuracy are everything. And as this experience shows, catching mistakes early is how teams build right the first time - and keep mission-critical projects on track.

Book a demo and discover how proactive QA can save your project from costly surprises.