-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions

Video

Digging It Right, First Time: How Real-Time Excavation Checks Prevent Future Delays

16 June 2025

On construction sites, progress often depends on what’s happening underground. A trench dug just a few inches off-spec can create ripple effects that slow projects, require costly rework, and disrupt schedules. That’s why our team treats even the earliest stages of construction - like excavation - as critical points for quality assurance.

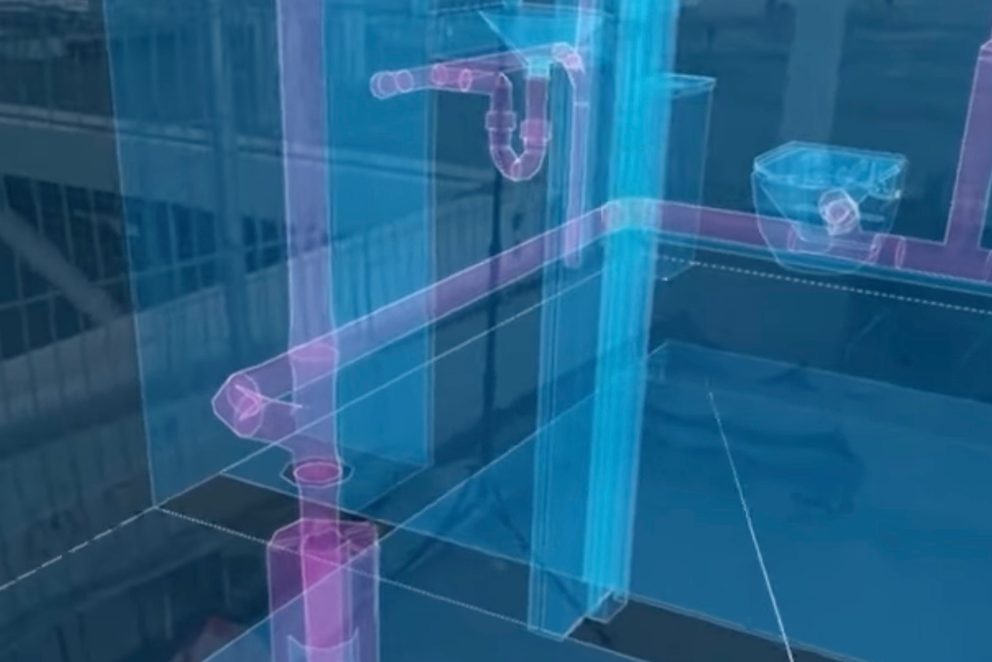

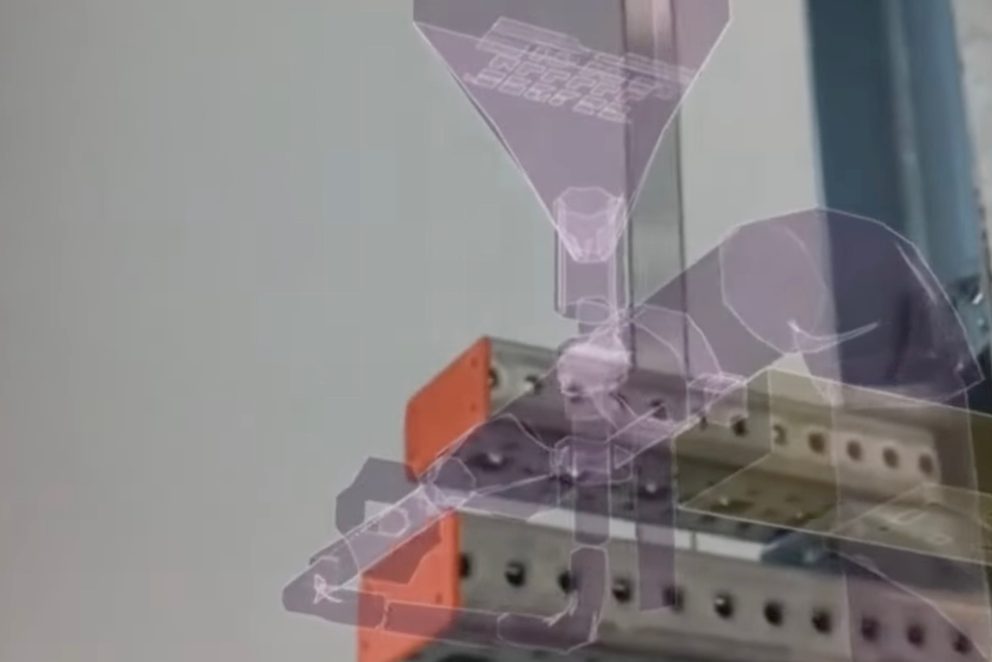

Recently, during a live excavation on one of our projects, we carried out a proactive check to ensure the trench would precisely accommodate a hydrant pipe planned for installation in that area. Instead of waiting until excavation was finished, we assessed the trench dimensions as the digging progressed, comparing real-world measurements to the digital model.

This approach has significant advantages. By verifying depth, width, and alignment in real time, we can confirm immediately whether the excavation matches the design requirements. In this case, the check showed the trench was excavated correctly, clearing the path for a smooth hydrant pipe installation without any redesigns or delays.

Catching discrepancies during excavation rather than after the fact prevents headaches later on. Rework on installed systems like hydrant pipes can be time-consuming and expensive, especially when multiple trades are involved. By checking early, we protect both the schedule and the budget, ensuring that each subsequent phase of work proceeds exactly as planned.

This is how modern QA/QC works: using digital models and real-time verification to turn potential risks into confirmed precision. When teams check their work as they go, they’re not just digging holes -they’re laying the groundwork for successful, seamless project delivery.

Precision today means progress tomorrow. And in construction, that’s a winning formula.

Book a demo to see how real-time QA/QC keeps your projects moving forward.