-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions

Insights

Mission critical accuracy: Augmented reality technology leads the way

05 April 2023

The construction industry needs a shakeup. Unfavorable economic conditions, high material costs and labor shortages make it harder than ever for construction teams to deliver projects on time and within budget.

This is especially true for large builds, where the risk of mistakes greatly increases due to asset complexity and the challenges in coordinating the multitude of teams.

McKinsey reports that 98% of hyperscale projects suffer cost overruns of more than 30%, and that the average slippage behind the original schedule is 20 months.

To combat the problem, forward-thinking industry leaders are implementing cutting-edge technologies to improve accuracy and quality control.

It’s no surprise that leading global construction firms such as Hensel Phelps and Turner Construction invest significant capital in tech startups or internal R&D initiatives to give them the innovative edge.

Achieving complete accuracy with Engineering Grade AR™

When the main contractor earned a US $400 million mission critical data center commission, they wanted to enhance their build processes with innovative technology to boost their quality control.

The contractor conducted exhaustive research into existing augmented reality solutions.

What they needed:

- Millimeter accuracy within construction tolerances

- Proactive real-time validation of work to replace laser scanning

- Seamless integration with their BIM platform (BIM360 from Autodesk)

- Quick deployment and ease of use.

The only solution that met the contractors strict criteria was the Atom™, the world’s most accurate Engineering Grade AR™ headset, giving build teams the power to view and position holograms of 3D models onsite with millimeter precision.

Mission critical data center project – the Atom’s delivers impressive ROI

The contractors utilization of the XYZ Engineering Grade AR solution enabled real-time validation in the field, identifying and rectifying 489 issues at 53% completion. This equaled a 3 - 6 month reduction in schedule.

As the XYZ solution comes as a fully managed service, a field applications engineer (FAE) was onsite to assist with data analysis and provide training.

“When we let contractors use the Atom, they immediately realized how it benefited everyone – it changed their whole perspective. From then on, they chased us to inspect their work before it was checked by the GC.” - Stephen Webber, Stephen Webb, Field Application Manager, XYZ Reality

Through its seamless integration with Autodesk BIM360, the Atom allowed a steady flow of information between field and office teams, ensuring everyone worked off the most up-to-date iterations.

The future of construction is groundbreaking tech

Contractors and project stakeholders understand that construction processes can’t continue in the current direction.

Accuracy needs to increase to prevent mistakes and eliminate rework, ensuring teams deliver projects on time and within budget.

If companies fail to adopt new technologies, they’ll be left behind by those that do.

Eradicate rework and build it right first time with the Atom.

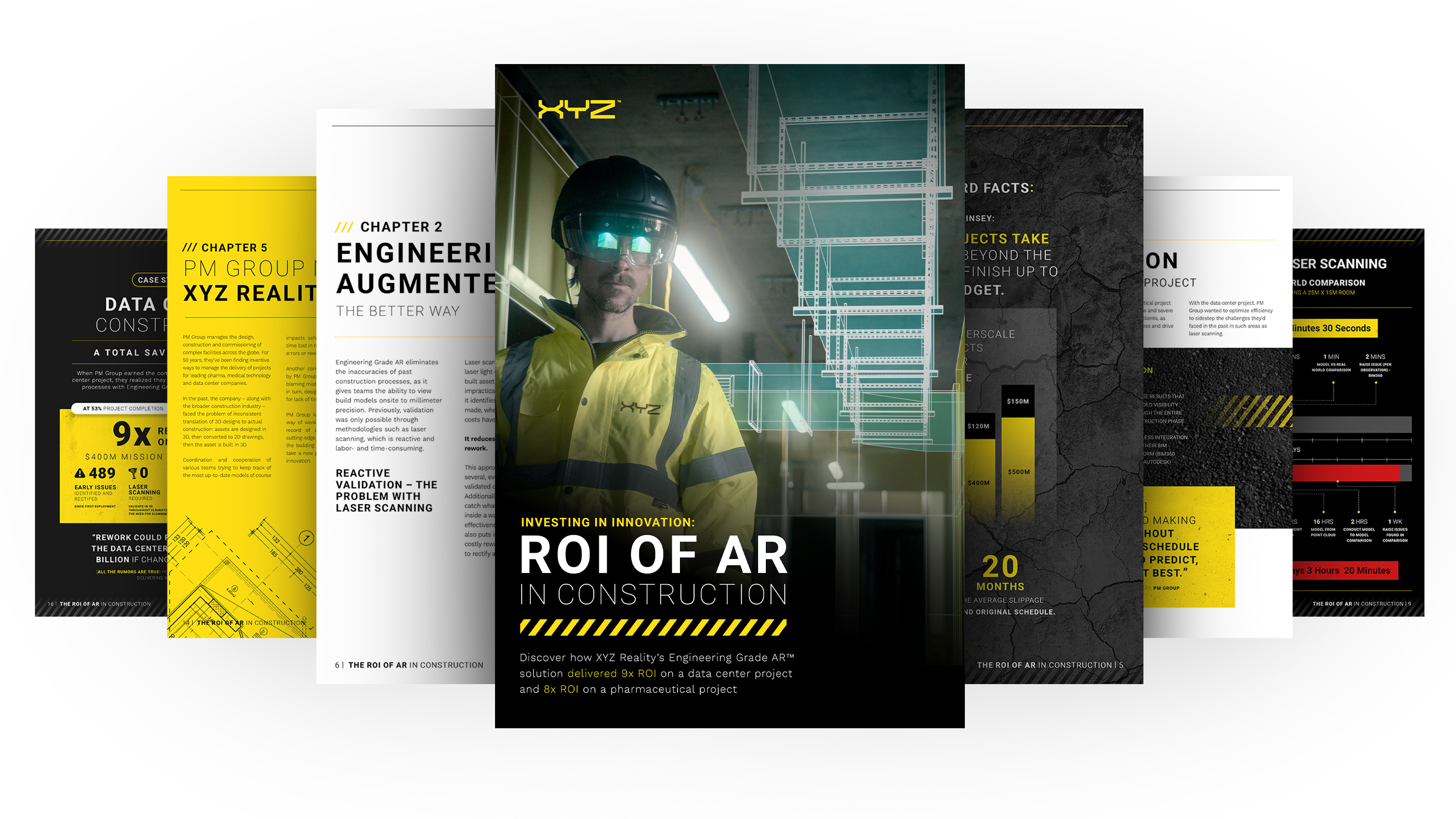

To learn more about how the Atom delivered 9x ROI on a mission critical data center project and 8x ROI on a pharma project, please download our new whitepaper Investing in Innovation: ROI of AR in Construction.