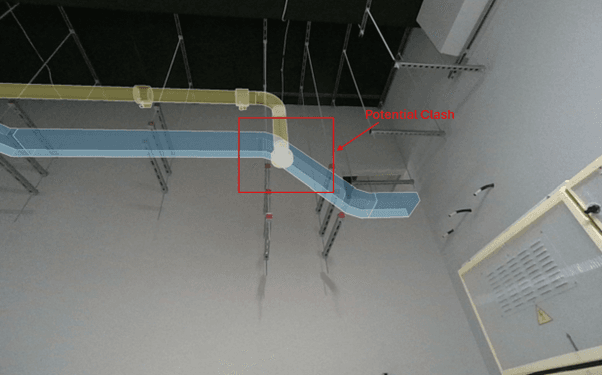

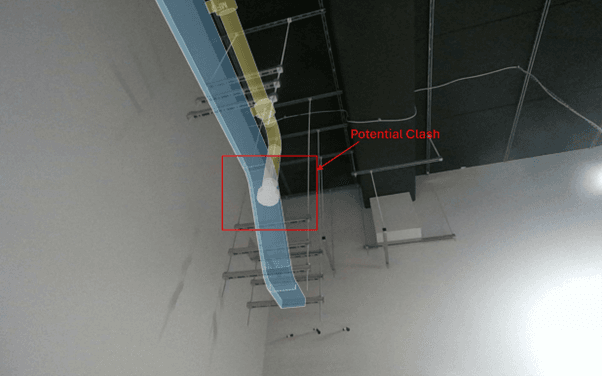

A leading data center operator is constructing a 30MW facility in France. Known for delivering scalable digital infrastructure across Europe, the client must meet aggressive delivery timelines while managing highly interdependent trades and technical systems. In this environment, undetected clashes or sequencing errors can cause significant delays and rework, making real-time progress tracking and proactive issue resolution essential for staying on schedule and within budget.

-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver construction's most powerful BIM platform to date

-

Built for

Built for

-

Industry

Industry

Understand how we support construction's biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions