-

Services

Services

Find out how we work with our clients and deliver value to construction projects from day one

-

Solutions

Solutions

Discover how all our solutions sync together to deliver constructions most powerful BIM platform to date

-

Industry

Industry

Understand how we support constructions biggest sectors, and hear from our clients who have experienced the power of XYZ

-

Resources

Resources

Get stuck into all our latest thought leadership, news, reports and industry leading content

-

Company

Company

Dive into what makes XYZ tick, unearth why construction is in our DNA and why we are world leaders in AR solutions

Insights

Repurposed technology in construction: Why it doesn’t work

22 June 2022

To close the productivity gap, construction must turn to ‘construction-first’ digital solutions, developed by those who have a complete understanding of the sector’s challenges and inefficiencies.

Digital innovation has the potential to revolutionize the construction industry. It’s a statement we’ve all heard a million times before, and there’s a simple reason it’s become a cliché: because it’s true. Back in 2019, Mckinsey & Company estimated that wholesale adoption of technology could improve productivity by around 14-15% and generate savings of around 4-5% - all of which could be added to the bottom line.

And while construction has made giant leaps forward in that small timeframe, it’s still characterized as the least digitized industry in Europe. In the last 2 decades, a meager 1% improvement in productivity has been achieved, and profit margins are still fixed at 5% despite the high financial risks associated with every project.

When looking for explanations behind the slow rate of digital adoption in the industry, commentators have been quick to point the finger at the construction companies who operate within it. But in truth, most organizations and leaders have a commendably proactive and flexible mindset. For instance, look at how construction firms responded to the challenges posed by COVID-19 to stay operational through challenging, completely unmitigated circumstances.

It’s wrong to suggest that the issue is rooted in the attitudes of contractors or their employers. The bigger picture is far more complex than that. And one piece of the puzzle that tends to get overlooked is the shortcomings of the technology available.

Construction knowledge unlocks construction solutions

Necessity is the mother of invention. An idiom that dates back almost 2,500 years but still rings true today. To rephrase Plato’s proverb (and to do so somewhat clumsily) a solution can only be delivered if the ‘inventor’ first has full knowledge of the problems they are trying to solve.

At XYZ Reality, we firmly believe that real industry knowledge is an essential prerequisite to the delivery of effective construction solutions. Our Founder & CEO, David Mitchell has years of hands-on on-site experience and has worked on some of the most prestigious construction projects recognized on a global scale including The Shard, Battersea PowerStation, and data centers throughout Europe. In addition to this, our Field Application Engineers have years of experience in land surveying, building surveying, spatial surveying, and engineering. So, if such solutions are being developed by ‘tech-first’ companies without adequate construction-sector insight, there are bound to be flaws which stifle efficacy.

Similarly, if the technology providers lack clarity on the problems they are trying to solve, then the users of that technology are likely to lack clarity on how it should be applied. A shovel is a fine tool for digging holes in the ground, but completely useless for drilling holes in timber.

To derive full value from construction technology, contractors must have a full understanding of how the tech works and what the technological output can offer in terms of process improvements. If tech is misapplied, it will quickly be labeled ‘unfit for purpose’ and consigned to the scrap heap.

Optimized construction technology

Building on this idea of construction-focused solutions for construction-focused challenges, another drawback of repurposed technologies are the extraneous bells and whistles which inevitably bear extra cost but don’t add extra value.

In the realm of Augmented Reality, many devices on the market can also be used for gaming, medical training and virtual tourism, in addition to 3D model visualization. Because of this, they include a range of complex features (binaural sound, for instance) that don’t actually benefit the contractor. Additionally, these tools fail to meet the on-site safety standards required on an active project site.

Not only does this drive-up costs, but unnecessary features also mean unnecessary complications in operation and a higher likelihood of glitches and malfunctions.

Highly specialized construction solutions (such as XYZ Reality’s Engineering Grade Atom™ headset) do exactly what they are designed to do, and they do it in the most effective, user-friendly way possible – having been field-tested over 50,000 hours. All of your investment goes towards rectifying on-site issues most construction teams need to solve.

Field-ready technology

Anyone who knows their way around a construction site will know that they are dusty, muddy, slippery, busy, often hazardous locations. Tech hardware that has not been designed with this in mind simply doesn’t tend to last very long in the field. Conversely, tech which has been developed by companies with an understanding of the realities of construction are far more likely to factor durability into their designs.

Connectivity is another issue. Most construction-specific technology is developed to function offline and to allow for synching when signal is re-established; an advantage in the field where remote locations or structural features can limit signal range.

But, like durability, construction-specific connectivity challenges are often overlooked by generic tech companies and as a result, non-construction hardware tends to be impractical when applied on-site.

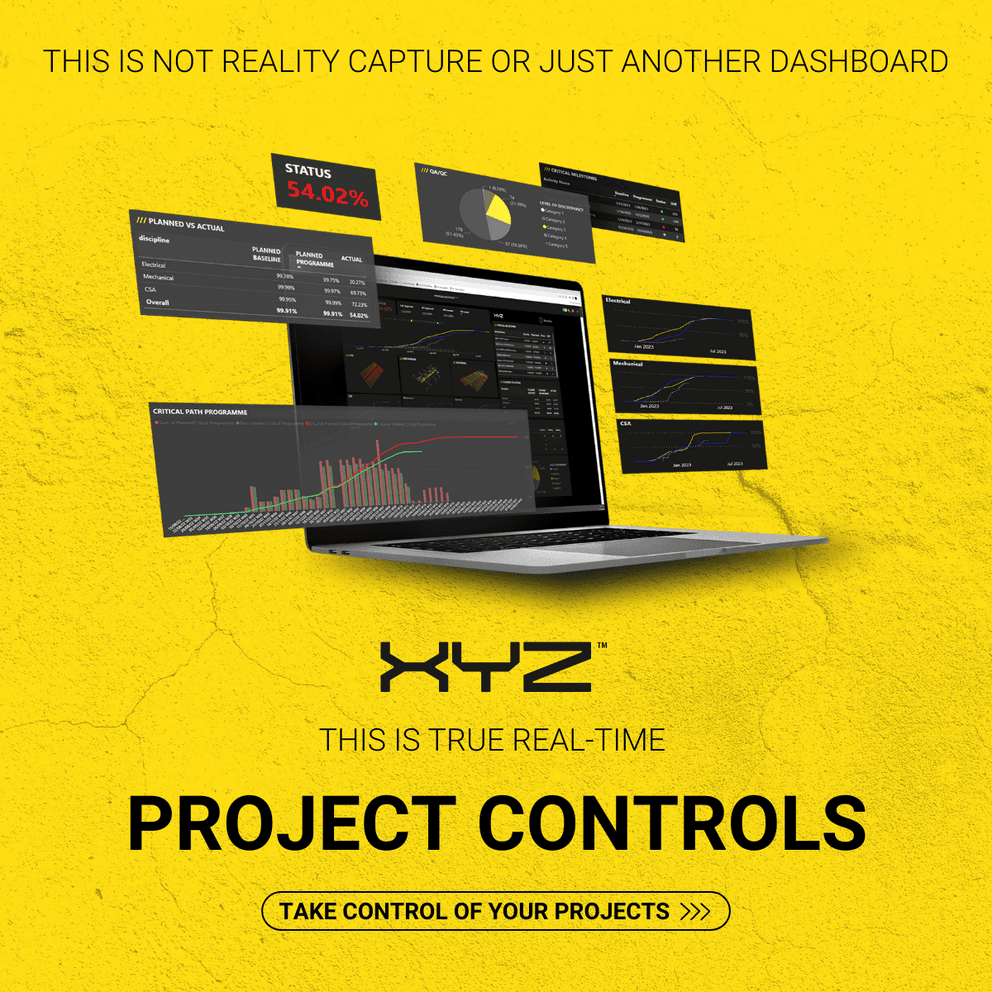

Integrating third party construction software

Another drawback of generic tech hardware repurposed for construction is that it relies upon third party developers. Such developers are likely to be highly specialized, which is fine for serving a specific purpose, but what this means in practice is that construction companies end up with a range of patchwork software solutions. This can be problematic for a number of reasons. For example, outputs from the tech are likely to be siloed, hard to manage and difficult to integrate with the wider organizational agenda.

Engineering Grade AR™, from a company that lives and breathes construction

In his own words, XYZ Reality Founder & CEO, David Mitchel says he “learned to walk on a building site,” and that he “grew up using a shovel.” (To dig holes - not drilling holes in wood!)

Taking up the family trade, he began his career as a contractor on domestic and commercial developments, then spent several years practicing architecture, before returning to construction as a Master Builder on major projects. This experience gave him unique insight into construction at all levels, helped him to understand where inefficiencies and problems arise, and gave him the knowledge and capabilities required to bring viable solutions to market.

Born out of a purpose to rethink, reset and reboot the out-of-date practice of 2D design, and building from 2D models, David recruited like-minded experts to launch XYZ Reality and build the Atom, the world’s first Engineering-Grade Augmented Reality headset. He recognized the potential benefits of Engineering-Grade Augmented Reality and he understood how it should be applied in the construction context.

The Atom, the world’s first Engineering-Grade augmented reality headset, enables users to view holograms on-site to millimeter accuracy. Designed and built entirely by XYZ Reality, the Atom uses proprietary software developed in-house which allows for two-way data flow, live validation, and seamless BIM 360 integration.

That’s why the Atom is so effective. It’s already unlocking proactive and real-time remediation and eliminating rework across construction sites around the world, saving developers millions upon millions of pounds and delivering over 9X ROI.

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=False, hidden_controls=False, loop=False, muted=False, full_width=False, width='1920', height='1080', player_id='77124216166', style='' %}

See what’s possible with XYZ Reality. Get in touch today and arrange a free demo of the Atom.